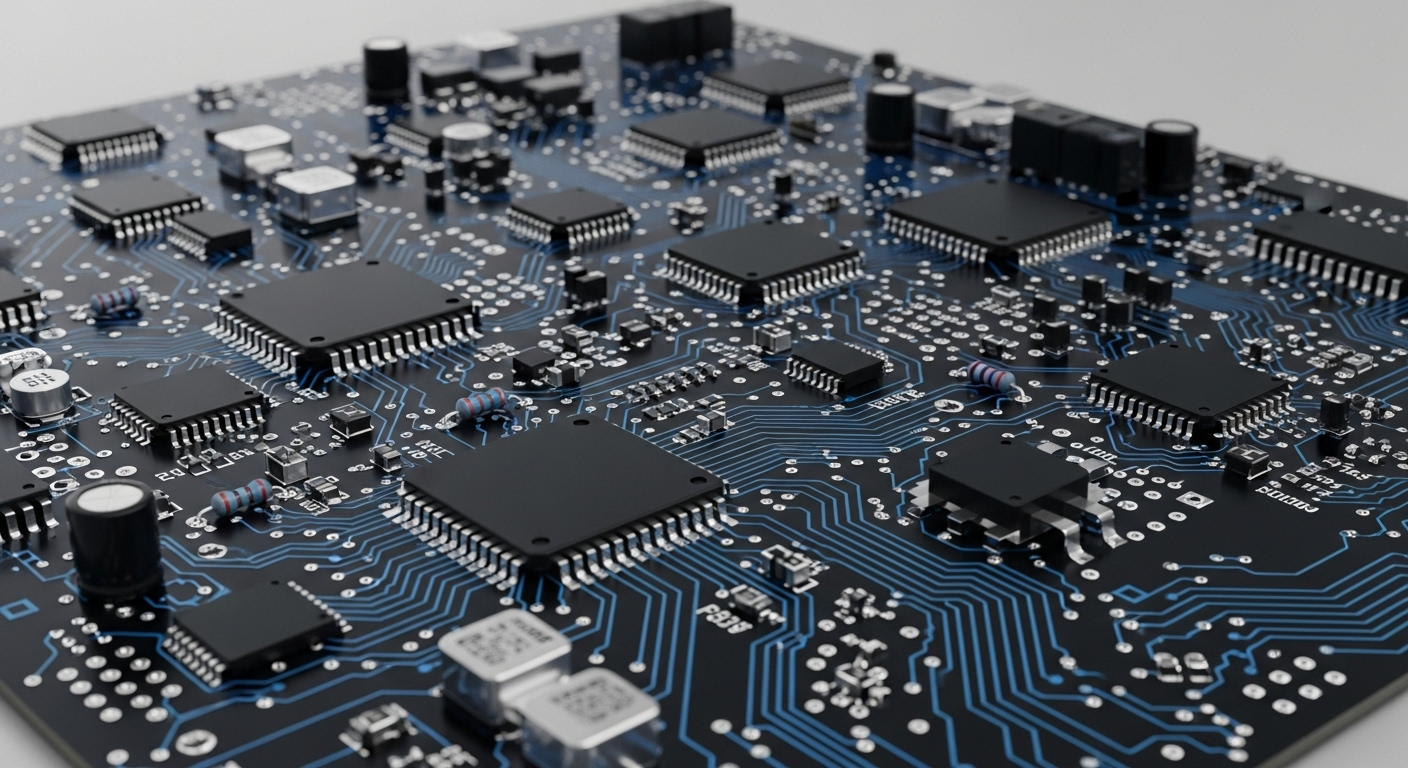

Printed Circuit Boards (PCBs) are the backbone of modern electronics. From smartphones to industrial robots, every device relies on a stable and efficient circuit board to function correctly. Over the years, PCB technology has evolved rapidly, offering advanced solutions that support high performance, compact size, and complex electrical requirements. Many engineers and electronics developers rely on resources like Zero PCB to explore basic-to-advanced PCB structures, fabrication methods, and testing processes.

Why Advanced PCB Solutions Matter Today

As industries move toward automation, higher processing power, and compact hardware designs, the demand for specialized PCBs has increased. Modern PCBs offer:

- High signal transmission

- Greater circuit density

- Improved heat resistance

- Flexible mechanical structure

- Longer product life

These features are essential in industries like telecommunications, robotics, automotive electronics, and aerospace systems.

Rigid-Flex PCB Technology

A Rigid-Flex PCB combines the durability of rigid boards with the versatility of flexible circuits. This hybrid design delivers:

- Better space efficiency

- Fewer connection points

- Higher vibration resistance

- Enhanced reliability in compact devices

Applications include cameras, medical devices, drones, and advanced robotic systems.

High-Frequency PCB Applications

High-frequency PCBs are used in systems that require fast signal transmission with minimal loss. They are made from specialized materials like PTFE, ensuring stable performance for:

- Radar systems

- 5G telecommunication equipment

- Satellite communication modules

- IoT devices

- High-speed routers

These boards are engineered to handle the demanding needs of modern digital communication.

Importance of PCB Assembly (PCBA)

PCB assembly transforms a raw circuit board into a complete electronic product. High-quality PCBA ensures:

- Accurate component placement

- Strong soldering and connectivity

- Minimal signal interference

- Proper thermal management

- Stable long-term performance

Advanced PCB manufacturers use automated SMT (Surface Mount Technology), optical inspection, and precise testing protocols to guarantee reliability.

Electronic Components in Modern Devices

Every PCB relies on a combination of components such as resistors, ICs, transistors, capacitors, and microcontrollers. Reliable component sourcing is vital because low-quality parts can cause:

- Signal distortion

- Overheating

- Device malfunction

- Shortened product lifespan

Using trusted suppliers and manufacturers ensures stable, high-performance electronic systems.

Telecommunications and Robotics: Key Industry Applications

Telecommunications

Modern communication systems depend on specialized PCBs for:

- Signal filtering

- High-frequency transmission

- 5G hardware

- Base station controllers

- Antenna systems

Robotics

Robots require advanced PCBs for:

- Motor control units

- Sensor processing

- Power distribution

- AI computing modules

- Communication interfaces

These boards help robots perform complex tasks with accuracy and speed.

Conclusion (100 Words)

PCB fabrication and assembly are essential parts of modern electronics development. With technology evolving at high speed, industries require advanced solutions such as Rigid-Flex PCBs and high-frequency circuit boards. These designs support compact hardware, improved durability, and faster data transmission. Many engineers and learners rely on resources like Zero PCB to understand foundational concepts and the technical aspects of PCB design. Choosing the right PCB manufacturer ensures reliable quality, stable performance, and long-lasting electronic products across telecommunications, robotics, and other high-tech industries.

FAQs

1. What is PCB fabrication?

It is the process of designing and manufacturing circuit boards for electronic devices.

2. What makes Rigid-Flex PCBs special?

They combine flexibility and durability for compact and high-performance devices.

3. Why are high-frequency PCBs important?

They support fast signal transmission for telecom and radar systems.

4. What is PCBA?

It is the assembly of components onto a PCB to create a functional electronic product.

5. Where can beginners learn basic PCB concepts?

Resources like Zero PCB explain PCB basics in simple and practical ways.